Brief Description of Fabric Manufacturing Process

Brief Description of Fabric Manufacturing Process

Fabric Manufacturing

Fabric Manufacturing is the process that converts the yarn to grey fabric through various processes such as winding, warping, sizing, denting, knotting, weaving, and inspection process, etc. This is one of the most important processes in textile manufacturing. Fabric is a thin sheet of cloth that is made from natural or manmade fiber by weaving, knitting, or non-woven process.

Process Sequence of Fabric Manufacturing Process

Weaving Process Flow Chart

1. Winding

- Cone Winding for Shuttleless Loom

- Pirn Winding for Shuttle Loom

- Cop Winding for Jute

- Sectional Warping

- Beam Warping

3. Sizing

4. Draw In or Denting

5. Knotting or Tie-In

6. Weaving

7. Inspection

8. Folding

9. Grey Fabric Delivered to Dyeing Process

Knitting Process Flow Chart

1. Cone Winding

2. Yarn In Cone Package Form

3. Attach the Yarn Package In the Creel

4. Feeding the Yarn in the Feeder

5. Set the Machine as per Design and GSM

6. Knitting

7. Withdraw the Roll Fabric and Weighing

8. Roll Making

9. Inspection

10. Numbering

11. Dispatch

Types of Fabric Manufacturing:

There are three types of fabric manufacturing processes. Following are the processes.

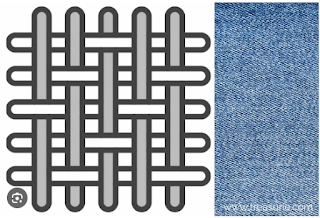

- Weaving: Weaving is the process of making fabric by interlacing warp and weft yarn. In this process, two sets of yarn interlace with each other. Weaving is the yarn crossing at right angles or strips of other materials to produce a flat or compact surface. Weaving is the most popular method for fabric formation. Woven fabrics are made by this process.

Fig: Weaving Machine - Knitting: Knitting is the process of making fabric by interloping warp and weft yarn. Knitting is the second most popular method for fabric formation. Knitting can be done either by hand or machine knitting, but the basic principle remains the same. i.e. pulling a new loop through the old loom. This process is used to make a knitting process.

Fig: Knitting Machine - Non-woven: Non-woven fabric is one type of fabric method that does not follow interloping or interlacing of yarn. Non-woven fabrics are fibrous sheet or web structure products by bonding or interlocking fibers by mechanical, thermal, or chemical process. Brading fabric is one example of nonwoven fabric.

Fig: Non-Woven Machine

Woven Manufacturing Process Details:

Woven fabric is the textile fabric which is formed by weaving. It is produced by interlacing of warp and weft yarns in a weaving loom.

(1) Winding Process:

Winding is the first process of woven fabric manufacturing process. Winding is the process of transferring yarn from one package to another to help the next process. The rehandling of yarn is an integral part of the textile industry.

Types of Winding in Textile:

1. According to Winding Package:

- Cone Winding Machine

- Cheese Winding Machine

- Pirn Winding Machine

- Flange Bobbing Winding Machine

- Cop Winding Machine

- Spool Winding Machine

2. According to Winding:

- Precision Winding Machine ( parallel or near parallel package)

- Non-precision Winding Machine (Cross Wound Package)

3. According to Drive:

- Direct Drive Winding Machine

- Indirect Drive Winding Machine

Cone Winding: Cone winding is the process of wounding the tube yarn into a knotless bobbin and during this process yarn default is removed. Cone winding is used to remove yarn faults, improve the quality of yarn, to was the yarn during the winding process. It also makes bigger packages from ring bobbin to get the continuous lengths of yarn for the subsequent processes such as warping, sizing, etc.

|

| Fig: Cone Winding Machine |

Pirn Winding: Pirn is a weft bobbin that is placed into a shuttle They are different from yarn packages as they are uniform in shape from one to the other. Bobbins are wound back and forth uniformly, while pirns are wound half an inch at a time. Pirn winding is the process of transferring weft yarn on the small pirn to facilitate the subsequent process for the shuttle loom. A tapered bobbin having weft yarn is known as pirn winding. It is used in end-feed shuttles.

|

| Fig: Pirn Winding Machine |

Cheese Winding: Cheese is a cylindrical spring tube that is used to wound as dyed yarn in dyeing industries. A nonwoven paper and thread need to wound the cheese so that the yarn does not damage. The cheese winding machine has fix blade mechanical type slub catcher, disc tensioner, and electrical top motion

|

| Fig: Cheese Winding |

Flange Winding: In this winding, two flanges contain both sides of the package and yarns are wound parallel. In this process, there is no necessity for traversing.

|

| Fig: Flage Winding Bobbin |

Cop Winding: Cop winding is used to collect the yarn on a package that can be useful in the twisting phase. Twisting is carried out during the yarn production.

Spool Winding: This winding is used to wrap string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

|

| Fig: Cop Winding |

|

| Fig: Spool Winding Machine |

Precision or Parallel Winding: When the successive coils of laid together and parallel or near parallel with each other, then it is possible to produce a very dense package. In this winding, very large yarn can be stored in a given volume. So that this is called precision winding. flange is not needed. With this winding, over-withdrawal can be possible. The yarn twist does not change in this winding. Side withdrawal cannot be possible with this winding and it is less stable.

|

| Fig: Precision or Parallel Winding |

Non-precision Winding or Cross winding: In cross winding, the winding package contains a single yarn which is laid on the package at an appreciable helix angle. Over-withdrawal is possible with this winding. The stability of the yarn package is good. Flanged is not needed in this winding.

|

| Fig: Non-precision or Cross Package Winding |

(2) Warping Process:

Warping is the process of parallel winding of warp ends from many packages (cone, cheese) to common packages (warp beam).

Types of Warping:

There are three types of warping used in the weaving process. They are described as follows:

- Beam Warping or Direct Warping: It produces the warper beams that are combined together into a single weaver beam in the sizing process. A warp beam may contain 500-1000 ends as the requirement in weaving construction. Direct warping is suitable for grey or mono-color warp yarns that require sizing.

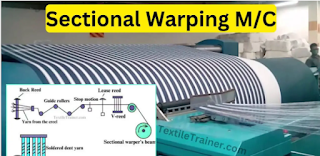

- Sectional Warping or Indirect Warping: Sectional Warping is preferred more than beam warping for multi-color warp. Here, the entire warping drum width is not developed simultaneously, it is developed section by section. It is also used for double/ grey or mono-color warps which do not require sizing. Here a weaver beam is produced as same as the sizing beam is produced in direct warping.

Fig: Sectional Warping Machine - Ball Warping: Ball warping is used to prepare logs for the rope dyeing machine. The ball is wound in a special wooden core which is called logs. Here magazine types of creels are used for the yarn creeping in the form of cheese. The no of ends taken one as per requirements of further processes that is for preparing the weavers beam. According to the number of ends in each group, the respective screening is done to make the required number of logs to be used at the creeping zones of the rope dyeing machine.

Fig: Ball Warping

(3) Sizing Process

Sizing is the process of applying an adhesive coating on the yarn surface. This process is the heart of weaving. Sizing is mainly done on woven fabrics, denim, and terry towels. Sizing is applied to the yarn to increase the weave performance of warp yarn by making it more resistant to weaving actions such as abrasion, tension, and friction.

Types of Sizing Process

- Pure Sizing: When the size pick-up percentage is about 3-10% then it is known as pure sizing.

- Light Sizing: When the size pick-up percentage is about 11-16 % then it is known as Light Sizing.

- Medium Sizing: When the size pick-up percentage is about 17-40 % then it is termed as Medium Sizing.

- Heavy Sizing: When the size pick-up percentage is above 40 % then it is termed as Heavy Sizing.

(4) Drawing-In or Denting Process

Reed: The reed comb-like structure that consists of regularly spaced wires. The term dent is commonly used to describe the space between two reed wires.

|

| Fig: Reed (Weaving) |

Denting: Denting means drawing the warp thread through the dent as required reed plan which determines the accuracy of the width of the fabric and the warp per inch.

|

| Fig: Denting Process |

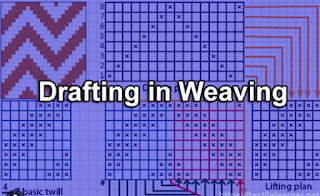

Drafting: Drafting is the process of selecting the harness or heald frame for individual warp threads according to the design.

|

| Fig: Drafting Plan |

Drawing-In: It is the process of pulling the warp threads through the heald eye of the heald wire.

(5) Tying-In:

Tying is used during the mass production of fabric. The warp tail end from the exhausted weaver's beam is tied to the beginning of the new warp. Therefore, if every end of the new beam is knotted with the old beam then the drawing-in process can be omitted. Following the tying-in process, all knots are pulled through the drop wires, heddles, and the reed.

(5) Weaving Process:

Weaving is the process of fabric manufacturing in which two distinct sets of yarns are interlaced at right angles to form a fabric. The textile art in which the distinct set of yarns, called the warp and the filling (weft), are interlaced with each other to form a fabric. The warp threads run lengthways of the piece of cloth and the weft yarn run sideways.

There are three basic structures of weaving for fabric manufacturing:

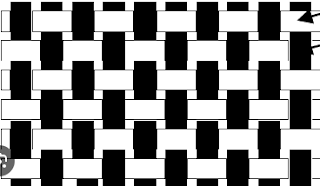

- Plain Weave:

Fig: Plain Weave Structure - Twill Weave:

Fig: Twill Weave Structure - Dobby Weave:

Fig: Dobby Weave Structure - Satin Weave

- Sateen Weave

- Honeycomb

- And many more

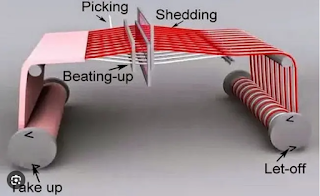

Primary Motion of Weaving

In order to interlace warp and weft threads to produce cloth on any weaving machine three operations are necessary:

A. Shedding: In this process, the warp threads run down the fabric into two layers to form a tunnel known as the shed.

B. Picking: In this method the weft threads, which traverse across the fabric through the shed

C. Beating-Up: Pushing the newly inserted thread into the shed is known as pick. In the already woven fabric at a point is known as fell.

Auxillary Motion of Weaving Loom:

|

| Fig: Primary Loom Motion |

To get high productivity and good quality of fabric additional mechanisms are added to a loom which is called auxiliary motion. The auxiliary motion is useful, but not as essential as the primary motion.

There are also three auxiliary motions in the weaving process such as let-off, take-up, and pattern.

|

| Fig: Schematic Diagram of a Weaving Loom |

Types of Weaving Loom:

Weaving looms are mainly divided into two types:

1. Shuttle Loom: Uses shuttle for picking. Shuttle contains pirn

2. Shuttleless Loom: In this loom, the shuttle is needed for the weft insertion. Rapier, projectile, was,ter, or air mechanism are used for the insertion of weft yarn instead of a shuttle.

Shuttleless Loom are six types. They are as follows:

- Airjet Loom:

Fig: Airjet Loom - Rapier Loom:

Fig: Rapier Loom - Power Loom:

Fig: Power Loom - Water Jet Loom:

Fig: Water Jet Loom - Projectile Loom:

Fig: Projectile Loom - Jacquard Loom :

Fig: Jacquard Loom

Grey Fabric Inspection: Grey fabric inspection is the process of identifying fabric weaving faults of the woven fabric just after the completion of grey fabric production. The main purpose of this process is to find out weaving faults and defects and generate quality reports of the fabric inspected.

|

| Fig: Grey Fabric Inspection |

Fabric Folding in Weaving: Fabric folding is the process of winding fabrics into clean, stretch-free folded form for easy packaging and transportation. It is the steps of fabric inspection which follow the inspection rules and cutting method.

Knitting

Knitting is the process of forming fabric by interesting loops from a single set of yarn. There are two types of knitting

- Warp Knitting

- Weft Knitting

Warp Knitting

Warp knitting is the process of forming fabric by knitting in which loops are made in a vertical way along with the length of the fabric from a single set of yarn and intereshing of loops take place in a flat form on a length-wise basis.

|

| Fig: Warp Knitting |

Weft Knitting

Weft knitting is the process of producing fabric by knitting in which the loops are made in a horizontal way from a single set of yarn and the intermeshing of loops take place in a flat form on a course-wise basis.

|

| Fig: Weft Knitting |

History of Knitting

1589- William Lee, the inventor of the mechanical stitch formation technique.

1758- Jedediah Stratt, the inventor of double knit technique.

1798- Monsieur Decroix, arranges the needle radially into coroma, which rotates and thus revolves the needles one after the other through the knitting stages.

1850- The circular knitting machine was first developed by English circular knitting frame. At first it was equipped by stationer bearded needle in vertical position. Then it was developed by setting latch needle which can be easily moved.

1878- Gris Wold, gets a potant for circular knitting machine which can be produce plain ribbed structure in any desired position.

1918- The double cylinder small circular knitting machine with double ended needle and slider was first developed in England by Firm Wildt.

Illustrate the Four Base Primary Structures of Weft Knitting Fabric

- Plain: Plain is the produced by the needles knitting as a single set, drawing the loops away from the technical back and toward the technical faces side of the fabric

- Rib: Rib structure is produced by operating two sets of needle in between each other so that wales of face stitches are knitted on each side

- Interlock: Interlock fabric was originally developed from rib but requires special arrangement of the needle knitting, back to back in an alternate sequence of fabric exactly in line each others.

- Purl: Purl is the only structure having certain wales containing both face and reverse loop. A garment length sequence such as fibber half has is defined as purl,

Feature of Knitting Machine

- The frame is normally free-standing and either or rectilinear according to the needle bed shape providing the support for the machine mechanisms.

- The machine control and drive system coordinated the power for the drive of the devices.

- The power co-ordinates machine control and drive system

- The yarn supply consists of the yarn packages or beam accommodation, tensioning device, yarn feed control, yarn feed carrier and guides.

- The knitting system includes the knitting element, their housing, drive and control, as well as associated pattern selection and garment

- The fabric take away mechanism includes stop motion, fault detectors, automatic oilers

Comments

Post a Comment