Desizing Process in Textile Industry

Desizing Process in the Textile Industry

Desizing

Desizing is the process of removing sizing material from the warp yarns of woven fabric. Sizing chemical consists of soluble starch material, a coupling agent, a lubricant, and, a range of additives

Types of Desizig Method:

1. Hydrolytic Method

- Rot steep

- Acid steep

- Enzymatic steep

2. Oxidative Method

- Chlorine

- Chloride

- Bromide

Objectives of Desizing

- To remove the sizing material from the fabric

- To increase the absorbency power of the fabric

- To increase the affinity of the fabric to the dyeing chemical

- To make the fabric suitable for the next process

Steeping

It is the process where soaking in the liquid (water) of a solid to extract flavors or to soften it.

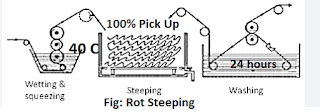

Rot Steeping

In rot steeping, the steeping cloth is passed through warm water of 40-degredegreeserature. For this clot, it is squeezed up to 100% expression by a squeezed roller and kept in washing for 24 hours.

Advantages

- Desizing agent warm water, no special chemical is used

- It is the cheapest and oldest way of steeping

- Time 24 hours

- Less weight loss

- The desizing process is used

- Less cost

Disadvantages

- More empty space required

- Take about 24 hours

- Less Production

- Hydro-cellulose form

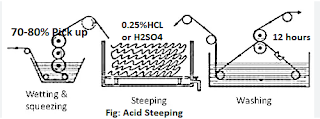

Acid Steeping

IIn acid steeping, fabrics are impregnated with a dilute sulfuric solution in a room where the temperature is 30 degrees and have to be it for (8-12) hours. Besides this, we have to remember that fabric should not dried in a storage room otherwise it may damage the fabric

Advantages

- Takes less time about (8-12) hours

- The desizing process is better

- Less space is required

- The most useful de-sizing process

- High production

- Starch fully liquified

Disadvantages

- Dilute sulfuric acid is needed as de-sizing agent

- Fabric may be damaged if it is kept it after drying

- High-cost process

- More weight loss

- Hydro-cellulose form

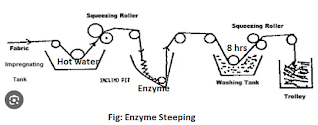

Enzyme Steeping

In enzymatic steeping, the fabric is passed through a hot water vessel where the temperature is 40C, then it is transferred to the enzyme (0.5-2)% both where 60-70 degree temperature is needed and have to keep it for 12 hours

Advantages

- The safest method of resizing

- The desizing process is good

- Takes about 8 hours

- Desizing agent enzyme

- Less space is needed

- High production

- No problem of hydro- cellulose

Disadvantages

- High-cost process

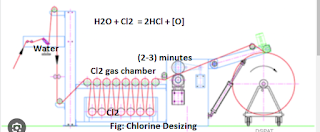

Chlorine Desizing

In chlorine desizing, the fabric is first dropped into a water vessel. Then, it passes into a chlorine chamber where Cl2 gas is traversed through the perforated bottom of the chamber. The chlorine gas reacts with fabric water and produces a small amount of dilute HCl and [O]. This incipient oxygen reacted with starch to remove this sizing material.

- Fully reactive process

- High production

- Take time ( 2-3) minutes

Disadvantages

- Need distilled water

- High maintenance

- Fiber degradation

- High cost

Estimation of Desizing Effect

- Measurement of weight loss percentage i.e. we get value of sizing material weight

- Tegawa Solution --- Iodine, Potassium iodine, methanol

It is used to indicate the amount of sizing material remains in the desizing fabric. when we fall one drop of tegawa solution into the fabric after desizing, if it is show a lighter color in the water. Then it indicates no sizing material remains in the fabric. If it shows a darkish color then it indicates there is sizing material remaion in the fabric

Comments

Post a Comment