Weaving Loom: Definition, Development, Motion,Types of Loom Details

|

Weaving Loom

A weaving machine is technically termed as a loom. Loos is a device or machine in which placement of warp and weft yarn is performed and thus produces fabric.

Chronological Development of Loom

1. Primetime or Vertical Loom

2. Pit Loom

3. Frame Loom

5. Hatlersley Loom

6. Ordinary Power Loom

7. Automatic Power Loom

8. Modern Loom

- Projectile Loom

- Rapier Loom

- Air Jet Loom

- Water Jet Loom

- Plain Multiphase Loom

- Circular Multiphase Loom

The Motion of Weaving Loom:

Every machine has a certain movement or motion. A loom can be distinguished from other machines by its specific motions or movements. Loom has three types of motion.

|

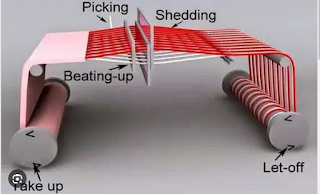

| Fig: Primary and Secondary Motion of Weaving Loom |

1. Primary Motion

- Shedding

- Picking

- Beat Up

2. Secondary Motion

- Take-up

- Let off

3. Tertiary Motion

Shedding: Shedding is the dividing of warp threads into two layer or parts one above the other for the passage of the shuttle.

Picking: Picking consists in passing a pick-off weft from one selvage to other selvedges of a cloth through the division of warp thread.

Beat Up: Beating up consists in beating up the last inserted pick weft to the 'fell of cloth'.

Take-Up Motion: This operation mainly involves in taking up the cloth after being woven and the wound it to the cloth roller.

Let-Off Motion: This operation mainly consists in letting off the warp threads from the weavers beam when the cloth is taken up onto the cloth roller.

Tertiary Motion:

- Side weft fork motion

- Central weft fork motion

- Warp stop motin

- Weft patterning motion

- Weft replenishment motion

- Loose-reel replenishment motion

- Fast-reel replenishment motion

Air Jet Loom Features:

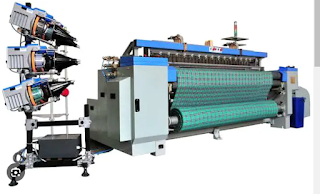

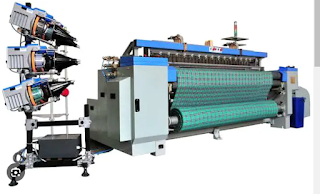

Fig: Air Jet Loom

Air jet loom weaving is a type of weaving where the weft yarn is inserted into the warp shed with compressed air nozzle. It combines high performance with low manufacturing requirements. The rate of weft insertion is extremely high of this machine. Air jet loom are primarily used for the economical production of standard fabrics, due to its exceptional performance. It can cover a wide range of styles. Heavy cotton fabric such as denim, terry fabrics, glass fabrics, glass fabrics, tire cord etc.

Advantages of Air Jet Weaving Loom

- High Productivity

- Consumption is less

- High weaving rate

- Operation is simple and less risk due to few moving parts.

- Less space is needed.

- Noise and vibration level is low

- Less spare parts required

- Reliability and minimum cost requirements

Water Jet Loom Features:

Fig: Water Jet Loom

Water jet loom features are described as follows:

- In the water jet loom, weft yarn package weight varies from 3.6-4.1 kg

- Treated water is used by the pump nozzle

- It consumes less power than others.

- Weft insertion no is higher in the water jet loom than air jet loom (normally 600 ppm)

Water Jet Loom Advantages:

- Less noise and vibration is produced in this loom

- No compressor is needed

- Water can be reused

- Minimum warp shed

- It runs by crank type shedding which is the cheapest in terms of power consumption

- Picking does not create frictional forces

Limitations and Energy Consumption of Air and Water Jet Loom

- Air and water jet loom can produce fabric at higher speeds compared to the projectile and rapier looms

- High power consumption results in high costs consume.

- Difficult to control the air flow and heat waste produced by the compressors is sometimes wasted

- Air and water jet looms are save energy costs.

- The rapier and projectile looms produce a lot more heat and so ait conditioning is often installed keep temperatures down within the factory

Features of Projectile Loom:

Fig: Projectile Loom

- The projectile loom use a projectile equipped with a gripper to insert the weft yarn across the shed

- It allows any types of cotton yarn, wool, mono or multi-filament and even hard fibers like jute and linen

- It available in two or four color with working width of 190-540cm.

Features of Rapier Loom:

Fig: Rapier Loom

- Rapier loom can weave very light fabric of 20 gsm to heavy 850 gsm

- The gripper head can take a wide range of count of yarn which ranges from 5- 1000 tex

- weft yarn can be inserted up to 16 different types.

- Weft insertion is done by rigid or flexible rapier

- It use two thin wire rods to carry the fill yarn and can operate at a speed of 510 picks per minute.

- Mostly used for spun yarn to make cotton and woolen and worsted fabrics

- In a double rapier loom, two rods moves from each side and meet the middle

Features of Plain Multi-Phase Loom:

Fig: Plain Mult-Phase Loom

- Continuous weft insertion occurs

- An ever-changing warp shed is required, which is called wave shedding

- There are occasionally six sets of sectional harness for each shuttle and each sets require a cam unit

- Each shaft must be connected with adjacent shafts by level gears

- Four sets of the harness are required for 2/2 twill

Features of Multi-Phase Circular Loom:

Fig: Multi-Phase Circular Loom

- The precision system of the shuttle and reciprocating parts is heavy

- Medium and coarse fabric can be produced

- Magnetic block and pinion propulsed metallic shuttle

- Vertical shed and wave shed is produced

- Horizontal heald frame.

- For plain weave thirty-two harnesses are used

Weaving Loom Manufacturer:

- A number of companies which produce different types of loom

- Some of them are Donier, Metex, Nuovo Pignone, Picanol, Saurer, Somet, Staubli, Sucker Muller, sultex, Sulzer, Vamatex, Van de Wiels etc.

- A loom can be described as Dornier jacquard rapier loom, 1994, nominal width 190 cm, 8 color selectors.

Comments

Post a Comment