Winding Process in Weaving: Objectives, Parameter, Packages and Advantages

Winding Process in Weaving

Winding is a process of transferring yarn from rings, bobbins, hanks, etc. into a convenient form of a package containing a considerably long length of yarn. This simple transfer of yarn from one package to another large package is called winding.

Objectives of Winding:

- To get a suitable package

- To get a quality fabric

- To empty the spinner bobbin so that it can again in spinning time

- To clean the yarn

- To store the yarn

- To shorter the labor of the worker

- To improve the efficiency of yarn in the next process.

Requirements of Winding:

- Minimum fault level

- No change of yarn

- Easy winding

- Suitable size and shape of a package

- Economical condition

- Avoid excess looseness and tightness

- Cheap cost of package

Winding Parameter

- Winding rate = m/min

- Winding dia = cm

- Yarn traverse velocity = m/s

- Angle wind = 0

- Surface velocity = m/min

- Net winding velocity = m/min

Types of Packages Used in Winding:

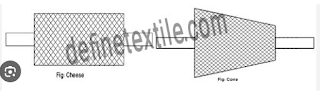

- Cone Winding: Cone winding is the process of wounding the tube yarn into a knotless bobbin and during this process yarn default is removed. Cone winding is used to remove yarn faults, and improve the quality of yarn, to was yarn during the winding process. It also makes bigger packages from ring bobbin to get the continuous lengths of yarn for the subsequent processes such as warping, sizing, etc.

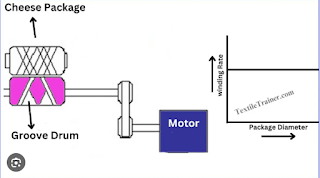

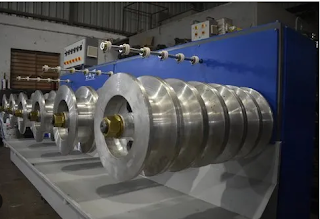

Fig: Cone Winding Machine - Cheese Winding: Cheese is a cylindrical spring tube that is used to wound as dyed yarn in dyeing industries. A nonwoven paper and thread need to wound the cheese so that the yarn does not damage. The cheese winding machine has fix blade mechanical type slub catcher, disc tensioner, and electrical top motion

Fig: Cheese Winding Machine - Spool Winding: This winding is used to wrap string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

Fig: Spool Winding Machine - Pirn Winding: Pirn is a weft bobbin that is placed into a shuttle They are different from yarn packages as they are uniform in shape from one to the other. Bobbins are wound back and forth uniformly, while pirns are wound half an inch at a time. Pirn winding is the process of transferring weft yarn on the small pirn to facilitate the subsequent process for the shuttle loom. A tapered bobbin having weft yarn is known as pirn winding. It is used in end-feed shuttles.

Fig: Cone Winding Machine - Cop Winding: Cop winding is used to collect the yarn on a package that can be useful in the twisting phase. Twisting is carried out during the yarn production.

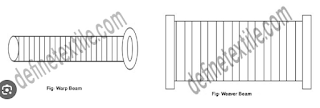

Fig: Cop Winding Machine - Beam Winding: In beam winding the full width of the warp yarns in a single winding operation on the warping beam.

Fig: Beam Winding Machine - Flanged Bobbin Winding: In this winding, two flanges contain both sides of the package and yarns are wound parallel. In this process, there is no necessity for traversing.

Fig: Flanged Bobbin Winding

Types of Package Winding:

- Parallel Winding

- Near Parallel Winding

- Cross Winding

Parallel Winding: This type of flange contains both sides of the packages and the yarns are wound parallel. In this process,, there is no necessity for traversing.

Advantages of Parallel Winding:

- Many yarns are wound parallel at the same time

- No need for a traversing mechanism

- No change of yarn twist

- This is stable

- Side withdrawal is possible

Disadvantages of Parallel Winding

- Two sides of the package need separate flanges

- For yarn unwinding and separate mechanism

- Cannot be over-withdrawal

- Example: Flanged bobbin etc.

Near Parallel Winding

This package contains only one yarn and the yarn is wound near parallel layers containing a continuous inner side of the package.

|

| Fig: Near Parallel Winding |

Advantages:

- No need for a flange

- No change of yarn twist

- Can be over-withdrawal

Disadvantages:

- Cannot be a side withdrawal

- This is not stable

- Need of traversing mechanism

- Example: Cop

Cross Winding:

Advantages:

- No need for a flange

- The yarn package is stable

- Can be over-withdrawal

Disadvantages:

- Need of Traversing Mechanism

- Yarn twist is changed in this process

- Ballon size is formed during unwinding. Example: Cone, cheese, etc.

Tensioning Device

The device that is used to give proper tension to the yarn during the time of winding is called a Tensioning device.

Importance of Effect of Tensioning Device

1. Too high tension:

- Can damage the yarn

- The breakage rate may be greater

- The elongation property of yarn can damage

2. Too low tension

- This can lead to unstable or loose packages that will not unwind clearly

3. Variation of yarn tensioning in different parts of wound packages can have undesirable effects.

4. Fow man-made filament yarn

- Can cause molecules to change

- Variation in color shading

5. For stable or spun yarn:

- Too high tension may break the yarn of this place.

Types of Tensioning Device:

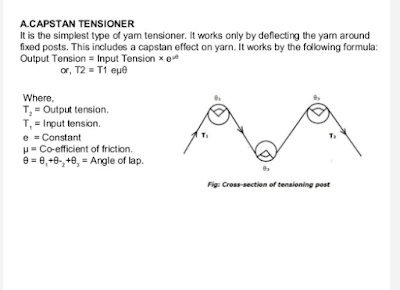

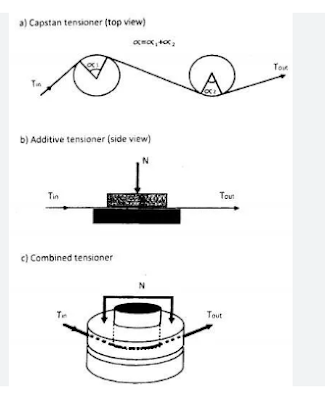

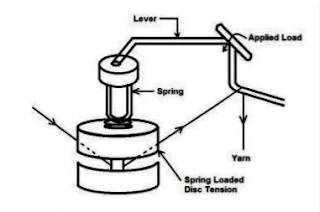

- Capstan Method:

2. Additive Method:Fig: Capstan Method Fig: Capstan Method, Additive Method, and Combined Method

Factors Influence for Selection of Tensioner:

- The device must be reliable to control uniform tension.

- It must be easily threadable

- It must neither introduce nor magnify tension variation

- It must not introduce the differences in a twist.

- It must be adjustable

- It must be affected by wear.

- It must not affected by the process of oil and dust

- It must not be encouraged by the collection of oil and dust

- It must be capable of easy clearing

- It must be inexpensive or cheap

- The operation surface must be smooth

Yarn Guide:

In unwinding and winding, it is necessary to control the yarn path for side-withdrawal. The yarn can pass along a smooth varying yarn path. But for overwithdrawl due to the vibratory force present the yarn must be controlled by placing guides along the yarn paths.

The yarn guides are made of hard smooth steel or ceramic:

Types of Yarn Guide

- A yarn end is required for threading

- A yarn end is not required for threading

|

| Fig: Yarn Guide |

Yarn Cleaner: Yarn cleaner is a device that is used to remove the following faults of yarn to remove the following fault of yarn to increase the yarn quality and weaving efficiency.

The following faults are removed by yarn cleaner.

- Thick and displaced yarn

- Slub and neps

- Loose fiber

- Foreign material etc

Yarn cleaner can be divided into two types:

1. Mechanical Type

- Conventional blunt blade type

- Serrated blade type

2. Electrical Type

- Capacitance type

- Photo-electric type

Comparison Between the Mechanical and Electrical Type

- Electrical clearer are more sensitive than mechanical clearer

- In the case of mechanical clearing, there is an abrasion between yarn and clearer parts, but in the case of electrical clearing there is no such abrasion

- Mechanical clearer does not allow some soft slubs from escaping through clearer whereas an electronic clearer does not allow passing any type of fault

- Mechanical clearer does not break the thin places and the length of the fault is not considered.

- Mechanical clearances are simple and easy to maintain while electronic clearances are costly. Require high standard maintenance.

Method of Driving:

- Surface Contact Winding

- Direct Driving at Constant R.P.M

- Direct Driving at Variable R.P.M

Surface Contact Winding:

In this process, the package is placed in contact with the surfaces of the drum or roller this placement the winding frictional force and hence the yarn becomes twisted. This is the main advantage of this process. The diameter of the packages is inversely proportional to the r.p.m of the drum and gets driven from the motor.

|

| Fig: Surface Contact Winding |

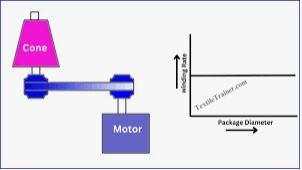

Direct Driving at Constant R.P. M:

In this process, the package is placed up in a spindle, and with the help of rollers, the spindle gets driven. The yarn is passed through the yarn guide for winding in packages. Here, spindle and package rpm are fairly constant. So, the diameter of the packages is directly proportional to the yarn take-up rate. For this reason, the yarn gets tension and there is always a breakage tendency.

|

| Fig: Direct Driving at Constant rpm |

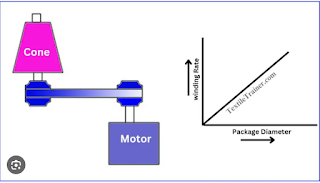

Direct Package Driving at Variable Speed:

In this method, the yarn package is driven directly at a variable speed to give a constant yarn take-up speed. It is necessary to cause the rotational speed to vary inversely with the package radius.

|

| Fig: Direct Driving Winding at Variable rpm |

Winding Efficiency

The percentage expression of the ratio of actual production and calculated production is called winding efficiency.

Winding efficiency = Actual Production/Calculated Production * 100%

If actual production < calculated production then,

Efficiency loss = Calculated production- Actual Production/Calculated production*100%

The following factors depend on winding efficiency:

- Spindle or drawn speed

- Yarn count

- Yarn quality

- Workers efficiency

- Humidity

- Working load per tester

- Maintenance and over-hauling

- Power failure

- Creeling time

- Doffing time

Faults and Defects of Winding

- Formation of patches on the yarn

- Incorrect speed of winding

- Tension variation

- Dirty package

- Increase the shape of packages

- Picking fault

- Overlapping

- Two end mixing

- Mixing yarn of linear density

- Greasy and dirty yarn

- Poor yarn clearing and snarling

- Pattern winding which on the result of co-incidence

Difference between Precision Winding and Non-Precision Winding

Precision Winding

- The number of coils remains constant

- No air gaps exist

- The angle of winding 90 or near 90

- One or more yarn can wound the bobbin

- Package stability is less

- A flanged bobbin is needed

- During the time of winding, relatively more yarn tension is needed

- The density of the yarn package is more

- Parallel or Near Parallel arrangement of yarn coil

- More time is needed for yarn withdrawal from the packages

Non-Precision Winding

- The number of coils per traverse of the yarn guide decreases

- Have air gaps

- The winding angle is less than 80

- Only one yarn can wound the bobbin

- Stable package

- A flange bobbin is needed

- Relatively less yarn tension

- The density of yarn package is less

- The yarn coil is arranged in a traversal

- Yarn withdrawal from the package takes less time

Comments

Post a Comment