Printing of Cotton Fabric With Pigment

Printing of Cotton Fabric With Pigment

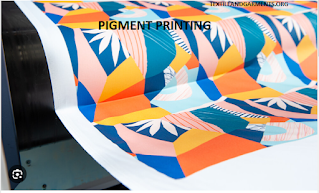

Pigment Printing

Pigment printing has gained much importance today and is the most commonly used technique for most fibers. Pigments can be used on almost all types of textile substrates. There are two types of screen printing.

- Rotary Screen Printing

- Flat Screen Printing

Objectives of Pigment Printing

- To print the fabric with print

- To know the function of used chemicals in printing

- To get the desired design of goods

- To get knowledge about pigment printing

- To get the desired shade

- To print cotton fabric

Sample Nature

100 % Cotton Knitted Fabric

Apparatus Required for Printing

- Beaker

- Glass Rod

- Pipette

- \Electric Balance

- Measuring Cylinder

- Screen

- Squeezer

- Curing Machine

Recipe Used for Pigment Printing

Sequestering Agent - 10cc/L

Pigment - 20 gm/Kg

Urea - 100 gm/Kg

Binder - 200 gm/Kg

Fixer - 10 gm/kg

Thickener - 30 gm/kg

Acetic Acid - 10cc/L

Function of Used Chemicals

- Sequestering Agent: Remove the hardness of water

- Pigment: Impart color to the printing paste

- Binder: Give stickiness and plasticity to the printing paste

- Fixer: It helps the binder to fixation

- Thickener: Increase the viscosity of the print paste

- Urea; Helps to fix the color of the fabric

Preparation of Printing Paste:

- At first, we take the required amount of pigment in a bath

- Then, a little amount of water is added to the pigment to mix the pigment

- Then required amount of thickener and glycerine is added

- The pigment mixer is stirred for a few minutes

Screen Printing Method:

- The fabric is placed on the printing table of the flat-screen printing machine

- Then the screen is placed on the sample fabric

- The printing paste is taken on the screen perforation

- Thus we can find the printed fabric with a smooth modern strike the paste is spread over the screen with slight pressure

- So that, the pigment particles can penetrate through the screen perforation

- Thus, we get the printed fabric

After-treatment of Pigment Printing

The printed fabric is steamed for (5-10) minutes in a cottage steamer and washed with cold water to remove unfixed pigment

Comments

Post a Comment