Dyeing Faults Causes and Remedies

Major dyeing faults in dyeing process is mentioned as follows.

- Uneven Dyeing

- Batch to Batch Shade Variation

- Patchy Dyeing Effect

- Roll to Roll Variation or Meter to Meter Variation

- Crease Mark

- Dye Spot

- Wrinkle Mark

- Softener Mark

Uneven Dyeing:

|

| Fig: Uneven Dyeing |

Causes:

- When uneven pretreatment occurs (i.e. uneven scouring and bleaching)

- Improper color dosing in the dye tank

- When high fixation dyes uses

- In case of synthetic fibers, uneven heat setting

- Lack of maintenance of dyeing machine

Remedies:

- Ensure even pretreatment

- Ensure even heat-setting in the case of synthetic fibers

- Proper dosing of dyes and chemicals

- Proper controlling of dyeing machine.

Batch to Batch Shade Variation

|

| Fig: Batch to Batch Shade Variation |

Causes

- Temperature fluctuation

- Dyes and chemicals improper dosing time

- Dyes and chemicals batch-to-batch weight variation

- Variation of dyes lot

- Improper liquor ratio, reel speed, pump speed

- Improper pretreatment

Remedies:

- By using standard dyes and chemicals

- The same liquor ratio needs to be maintained

- By following standard pretreatment procedure

- The same dyeing cycle needs to maintain

- An identical dyeing procedure should be followed

- The operators need to add the right bulk chemicals at the same time and temperature in the process

- The pH, hardness, and sodium carbonate content of supply water should check daily

Patchy Dyeing Effect

|

| Fig: Patchy Dyeing Effect |

Causes

- Fabric entanglement

- Alkali faulty injection

- Color improper addition

- Due to water hardness

- Due to the addition of improper salt

- During intermediate dyeing, dye migration

- Uneven heat in the machine etc.

Remedies:

- Proper pretreatment needs to be ensure

- Dyes and chemicals proper dosing

- Heat should be the same throughout the dye liquor

- Proper addition of salt

Roll to Roll Variation or Meter to Meter Variation

Causes

- Dyes poor migration property

- Improper solubility of dyes

- Water hardness

- Faulty machine speed, etc.

Remedies

- Use of standard dyes and chemicals

- Proper machine speed need to maintain

- Use of soft water

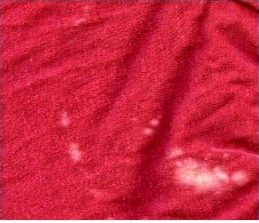

Dye Spot

|

| Fig: Dye Spot |

Causes

- Dye particles improper dissolving in batch

- Caustic soda particle improper dissolving in bath

Remedies

- Dyes and chemicals need to be properly dissolve

- Bypassing the dissolved dyestuff through a fine stainless steel mesh strainer

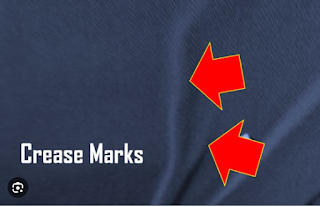

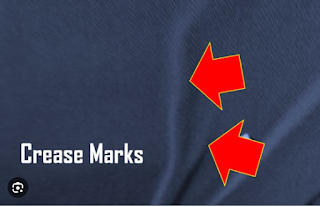

Crease Mark

|

| Fig: Crease Mark |

Causes

- The fabric rope poor opening

- Synthetic material shock cooling

- If pump pressure & reel speed in not equal

- Due to high speed machine running

Remedies

- Proper reel speed and pump speed maintaining

- Lower rate rising and cooling temperature

- Reducing machine load

- Higher liquor ratio

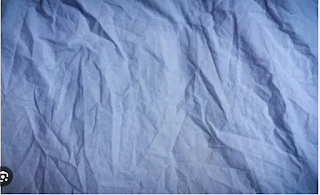

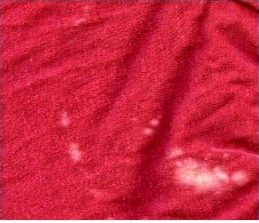

Wrinkle Mark

|

| Fig: Wrinkle Mark |

Causes

- The fabric rope poor opening

- Shock cooling synthetic material

- High temperature entanglement of the fabric

Remedies

- Maintaining of proper reel and pump speed

- Cooling the temperature and lower rate rising

- Liquor ratio need to be remain higher

|

| Fig: Softener Mark |

Causes

- Softerner improper mixing

- During application of softener, improper fabric running time

- Fabric entanglement during application of softener

Remedies

- Proper reel speed and pump speed should be maintained

- Proper mixing of softener before the addition of the softener

- During softener application, prevent the entanglement of the fabric

Comments

Post a Comment